Resources

Chapter 1

What is CNC Programming and how can it help you?

What is G-Code?

What are the different methods of CNC Programming?

- CAM Software

- Conversational Programming

- G-Code Programming

Why should I learn CNC Programming?

- Simple parts can be easier with g-code than CAM. You want a rectangular cover plate with 4 holes in it. If you’re proficient with g-code you’re done before you can create a CAD model, run it through CAM, get the gcode onto the machine, and run it. With Conversational CNC, you don’t even have to be proficient at g-code. For all those cases where you thought manual machining was faster, g-code or Conversational CNC will make the CNC machine an even better choice.

- Getting a Second Opinion on Your CAM Code. Even expensive CAM software can have bugs. Or, if they’re not strictly speaking bugs in the CAM, they may be problems with the post-processor. With just a little bit of knowledge about GCode and the help of a GCode Simulator, you can get a second opinion on the CAM-generated GCode and fix minor errors before you have to discover them on the machine.

- Specialized or Downstream Tasks that Complement CAM. As great as they are, CAM programs don’t do everything. There are many specialized tasks that are difficult or impossible to do with CAM. In addition, there are downstream tasks–things that come up when the job is actually on the machine that weren’t contemplated by the CAM or Post. Sometimes these tasks are relegated to GCode because the CAM software won’t do them. Sometimes it’s because the CAM is aiming at a generalized common denominator and something special comes up on the Shop Floor–for example, a slightly different cutting tool has to be used while we wait for another shipment of the normal tools. A simple feeds and speeds change in the gcode will handle it far faster than re-running the CAM, assuming we’re capable of making such simple changes.

What’s the Best Way to Learn G-Code?

G-Code is complicated.

G-Wizard Editor makes it easy

There Are Many Dialects of G-Code

How Are the Dialects Different?

Very Important:

How do the Dialects affect CNC Programming?

Exercises

Chapter 3

CNC Coordinates: Learn to do what manual machinists do on your CNC machine

CNC Coordinate System for G-Code and Machines

Mill Axes for a Typical Vertical Machining Center. Note: arrows show table motion in positive g-code direction. Handedness is spindle motion and reversed!

Lathe Axes for a Typical 2-Axis Lathe…

The cylinders in each drawing represent the spindle of the machine. Be sure to have a look at exactly how the axes are laid out on your machine. For example, horizontal mills are turned around considerably from the drawing I’ve shown. Lathes can get a lot more complicated than the simple 2-axis version I’ve shown.

4-Axis, 5-Axis, and More

Much more complex configurations are possible when you have more axes. For example, here is a 5-axis setup:

5-Axis Mill With Trunion Table…

Expressing Coordinates in G-Code

What About Units?

Incremental Versus Absolute Coordinates

Offsets

Planes

- XY

- YZ

- XZ

Conclusion

Exercises

Chapter 4

G-Code Cheat Sheets and CNC Programming Secret Weapons

G-Code Cheat Sheet? Now You’re Talking!

Chapter 5

Get Productive with CNC Programming Software

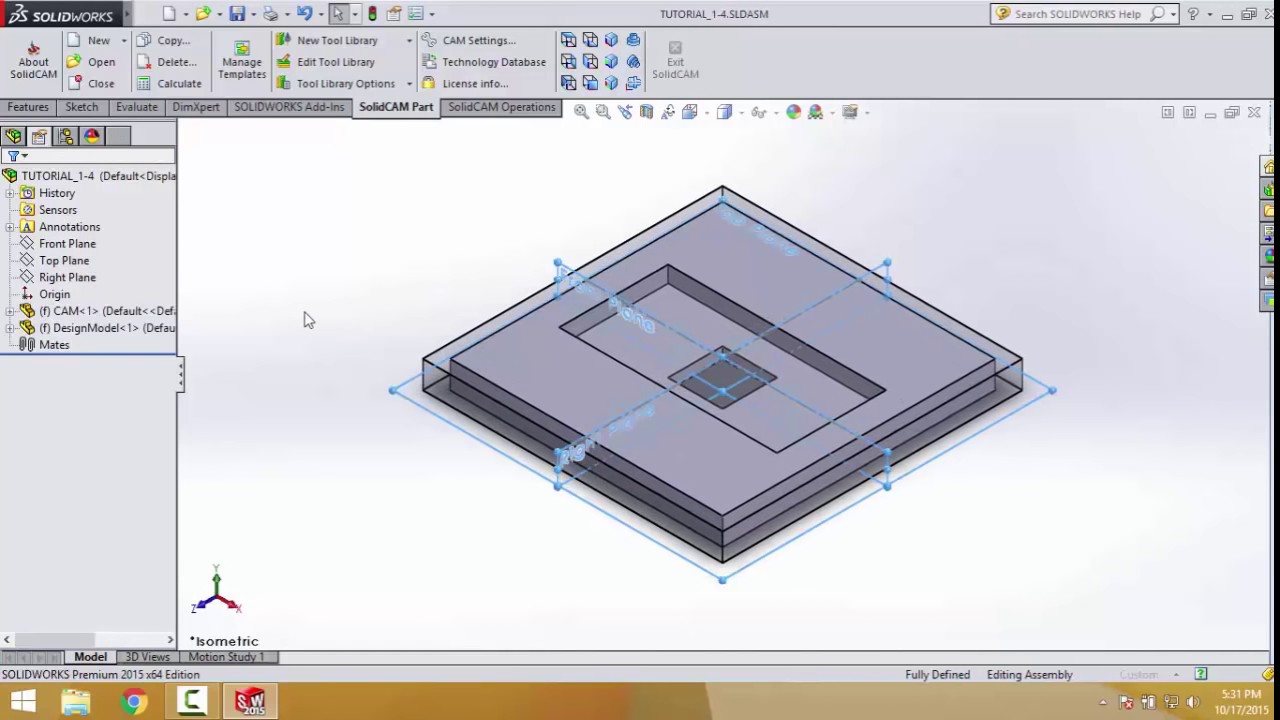

- CAM Software

- G-Code Editors

- G-Code Simulators

- Conversational Programming Software

21 Kinds of Digital Tooling for CNC“.

CAM Software

G-Code Editors

- Text Editing Features: These features determine how easy it is to edit the text of your program. The important thing is that these features know g-code syntax, and are not just the standard features any text editor has.

- Informational and Power Editing Features: These features give you extra power in understanding your program, or in creating it quickly.

- Program Revision Features: The features help you to make mass revisions to your program, for example, to renumber the program lines.

- G-Code Simulator and Backplotter Features: These features allow you to watch the g-code program execute in simulation.

- Error Checking Features: If your goal is to make sure the gcode is ready to run when it hits the CNC machine, you want to have comprehensive error checking right in your Editor/Simulator.

- Arc endpoints

- Arc center coordinates

- Arc angle

G-Code Simulators, Debuggers, Backplotters, and Viewers

- Your CNC Machine has what are called alarms. Certain things will trigger an alarm even though the backplot looks fine. A good simulator has alarms too so you can check your program and fix all the alarms before they show up on the machine.

- Macro Debugger. This is the ability to test and thoroughly understand g-code macros. Macros are the ultimate in CNC Programming power and flexibility, but they can be quite complex to create, understand, and debug. Hence a Macro Debugger is a valuable assistant when dealing with them.

- A Post Processor, just like your CAM Software uses. Most simulators don’t have a post. They make a lot of assumptions, which means they can’t accurately identify problems relating to g-code dialect. You want a simulator that has a post.

Conversational Programming Software

Which one is right for you?

Chapter 6

Get Your CNC Machine Ready to Run Your Program

Let’s Start With Part Zero (also known as Program Zero)

Cnc Programming Tutorial Pdf Free

What’s the difference between machine zero, work zero, part zero?

Establishing a Work Coordinate System via “Touch Offs” or “Zeroing”

Edge Finders and Probes for Establishing Work Coordinates

A simple edge finder…

And here is a demonstration of a Haimer 3D Taster:

Haimer 3D Taster…

Renishaw probe setting up work offsets on a VMC…

Each of these tools is similar in purpose, just with increasing capability, automation, and expense. There are a wide variety of other tools available for precisely locating features on your parts and workpieces. Some are more specialized, such as the Blake Coaxial Indicator, which is used to locate bore centers.